Aeronautical engineers work on applications such as manipulating an aircraft’s design to be more aerodynamic and efficient, estimating an aircraft’s propulsion needs and testing and analyzing these designs.

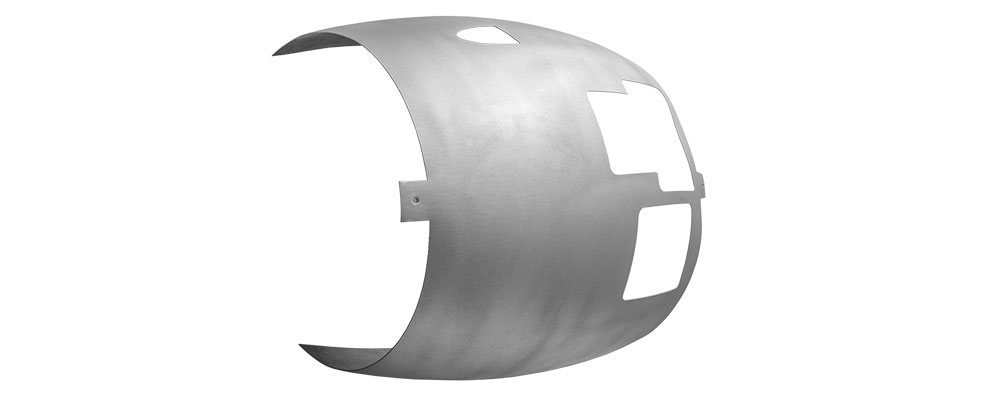

With this said many parts of airplanes and helicopters are made of metal and other materials. In addition to widely accepted industry-specific processes, especially machining, laser technology for years was considered unpractical but today also plays an essential role in the construction of new aircrafts.

Laser technology can be used to cut parts of the structure and fuselage, often made of aluminum or composite material, and reduces the manual reworking usually required to finish the components.

Recent studies confirm that the areas subject to overheating caused by a laser beam during the cutting process are not critical, and do not generate criticalities in the production cycle.

Moreover, laser cutting, unlike water-jet cutting, does not cause delamination’s on composite materials.